The importance of energy efficiency (EE) has increased significantly in the manufacturing industry as a result of stricter environmental regulations to mitigate climate change. Despite this, most manufacturing companies struggle to monitor energy efficiency in real time. It is crucial to have access to energy information and analyze it effectively to identify key indicators for successful energy management. These include, for example, energy consumption per production line, energy losses due to inefficient machines or unused production capacity. This is where Peakboard comes in: With our low-code platform, you create individual applications that are customized to the exact needs of your company. By visualizing and analysing key energy figures in real time, you have a comprehensive database to optimize your processes in the best possible way. By saving energy, you also make a major contribution to the climate.

With Peakboard, you get a comprehensive overview of the energy requirements in your production hall. You can always keep an eye on the energy consumption of individual systems and the process temperature of selected machines. For further analysis, you receive precise information in real time about the total consumption of the current day and the current month, as well as the change compared to the previous month. Download this free template to test the application right away. You can use OPC UA, MQTT, Siemens S7, Azure Event & IoT Hub, Mitsubishi Electric, Beckhoff Automation, Bosch IoT Gateway or Rockwell Automation as data sources.

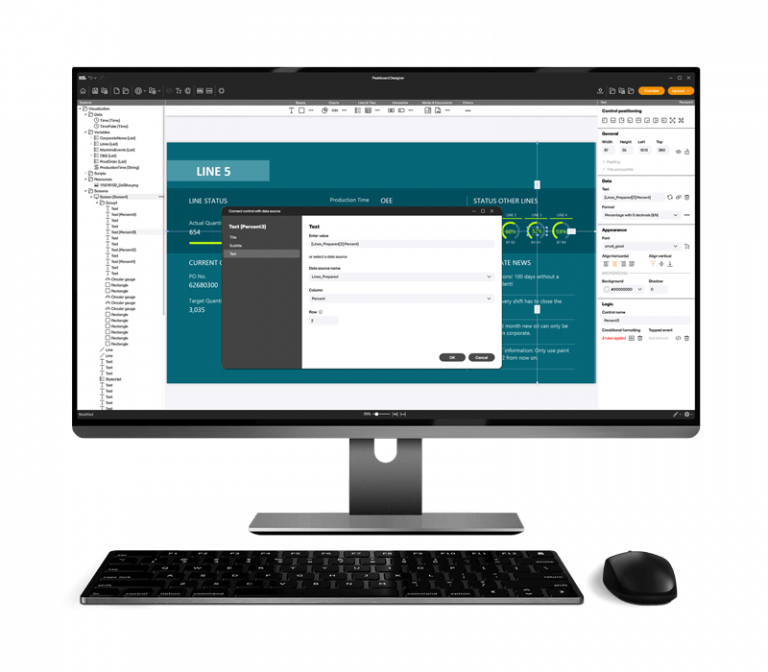

If the energy consumption of a particular machine suddenly rises sharply, it could indicate a possible malfunction. For a higher level of response, you have the option of setting automatic alarms and notifications to detect these fluctuations in energy consumption more quickly. This is particularly easy with our low-code software, the Peakboard Designer, because you can easily add additional functions and applications to your interactive dashboard. With the help of real-time data, it is possible to take direct action to check the machine, identify potential energy wastage and rectify it.

For long-term evaluation, Peakboard stores your data securely in Peakboard Hub. This allows you to recognize trends and identify minor deviations that may be overlooked in day-to-day operations. This comprehensive data basis makes it easier to plan further maintenance work. You can also recognize in good time whether a machine should be replaced. This not only saves you energy and money, but also contributes to sustainable production.

Capture, process and visualize your order data e.g. from SAP with the production data from your machine – in real time and without major programming effort.

Just download the software for free, install it on your PC and get started.