Optimized machine data integration with Kepware.

The key to networked machines

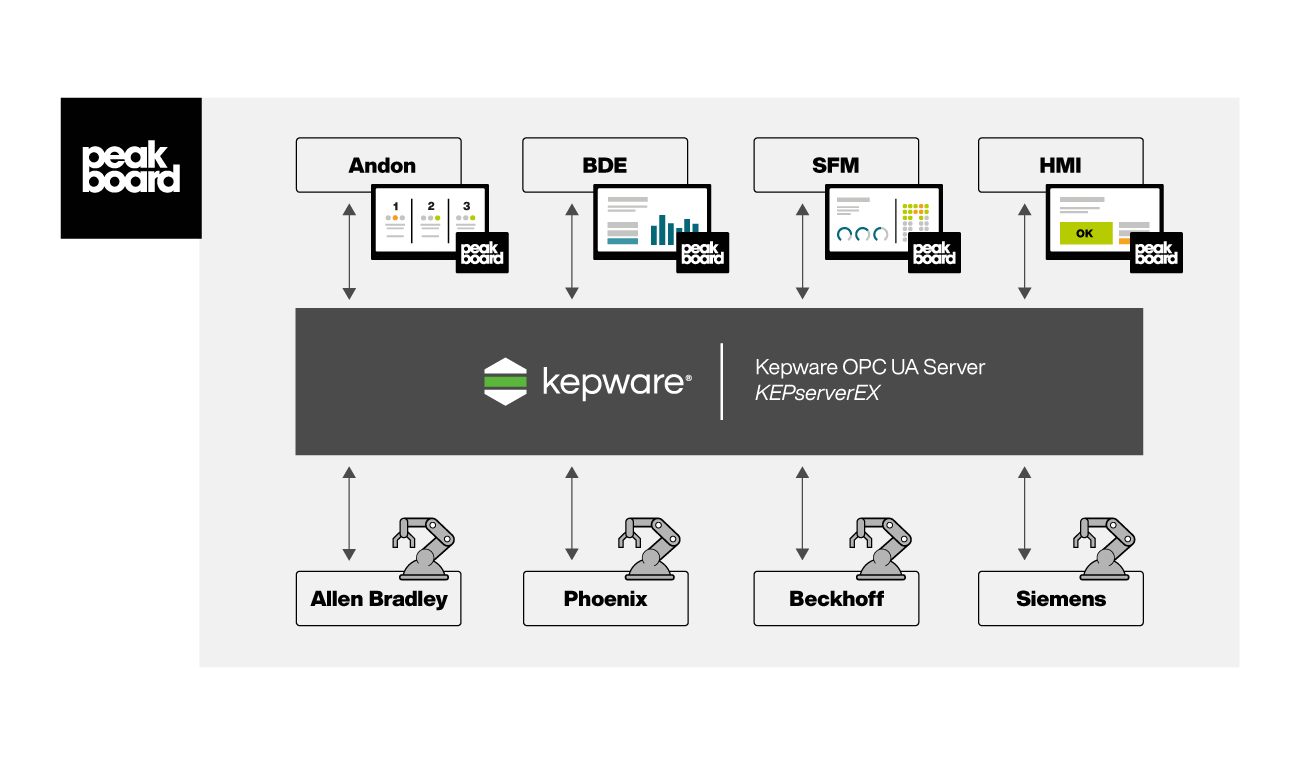

The standardization and efficient use of machine data are at the heart of our cooperation with Kepware. Kepware serves as a gateway to connect any type of machine via a standardized protocol, usually OPC UA or MQTT. In addition to the more than 100 different data sources that Peakboard already supports, the integration of Kepware opens up the possibility of using additional machine protocols. Another advantage of Kepware is that the data can be historicized in a database to enable detailed analyses. This creates an optimal data flow between machines and IPC devices without overloading any systems.

Kepware and Peakboard in harmony

Optimizing manufacturing processes.

Kepware offers a comprehensive portfolio of industrial connectivity solutions that help companies connect different automation devices and software applications. Thanks to a flexible and scalable architecture, drivers can be combined and multiple protocols can be used in a single server. Peakboard harmonizes with a company’s existing OPC UA or MQTT server from Kepware for fast connectivity and smooth data flow. Communication is bidirectional: the data can also be sent back to the machines via OPC UA.

Thanks to the structured available data, a company can transparently display KPIs such as OEE, cycle and shift times within a few seconds. In addition, the Kepware server saves the real-time data as a history, e.g. in an SQL database, for in-depth BI analyses.

Gateway for more efficiency in production

The OPC UA server from Kepware collects and standardizes data from many PLC manufacturers. At the same time, Peakboard offers interactive solutions as a low-code platform for applications such as Andon Boards, BDE, SFM and HMI. The collaboration between Kepware and Peakboard simplifies the integration of machine data into real-time dashboards and thus improves production processes.

Efficient load balancing for optimized performance

The Kepware network architecture.

The network architecture for Kepware deployments plays a critical role in ensuring robust and scalable data connectivity. By using load balancing techniques, the load can be distributed across multiple Kepware servers to ensure even utilization. This not only optimizes performance but also increases resilience by providing additional servers. A carefully planned network architecture enables companies to efficiently meet the requirements of their industrial automation and data integration processes.

Feel free to tell me about your project or ask me your questions. I’m already looking forward to hearing from you.